Scientists of today, farmers of the future

We are now living midst a food revolution. Every day we end up being closer to the point of no return from the way the things were before – and it’s a good thing. The future of food is not on the ground, but in the air.

Solein® is a microbial protein made with cellular agriculture. Cellular agriculture, or cellular farming, is a sustainable method of producing food that does not compromise environmental stability; safe and nutritious food can be produced even under the most challenging environmental conditions. As Solein needs no farmland to grow, its production is virtually independent of location. It can be grown anywhere, in the middle of cities, the frozen Arctic or in deserts, with minimal resources.

The production process for Solein is scalable in any geography to create a protein to support the rising demand. Solein accomplishes this by radically condensing the process of protein production. Instead of needing vast arable lands, water, other resources, and time that other proteins require, Solein can be grown from start to finish under one factory roof.

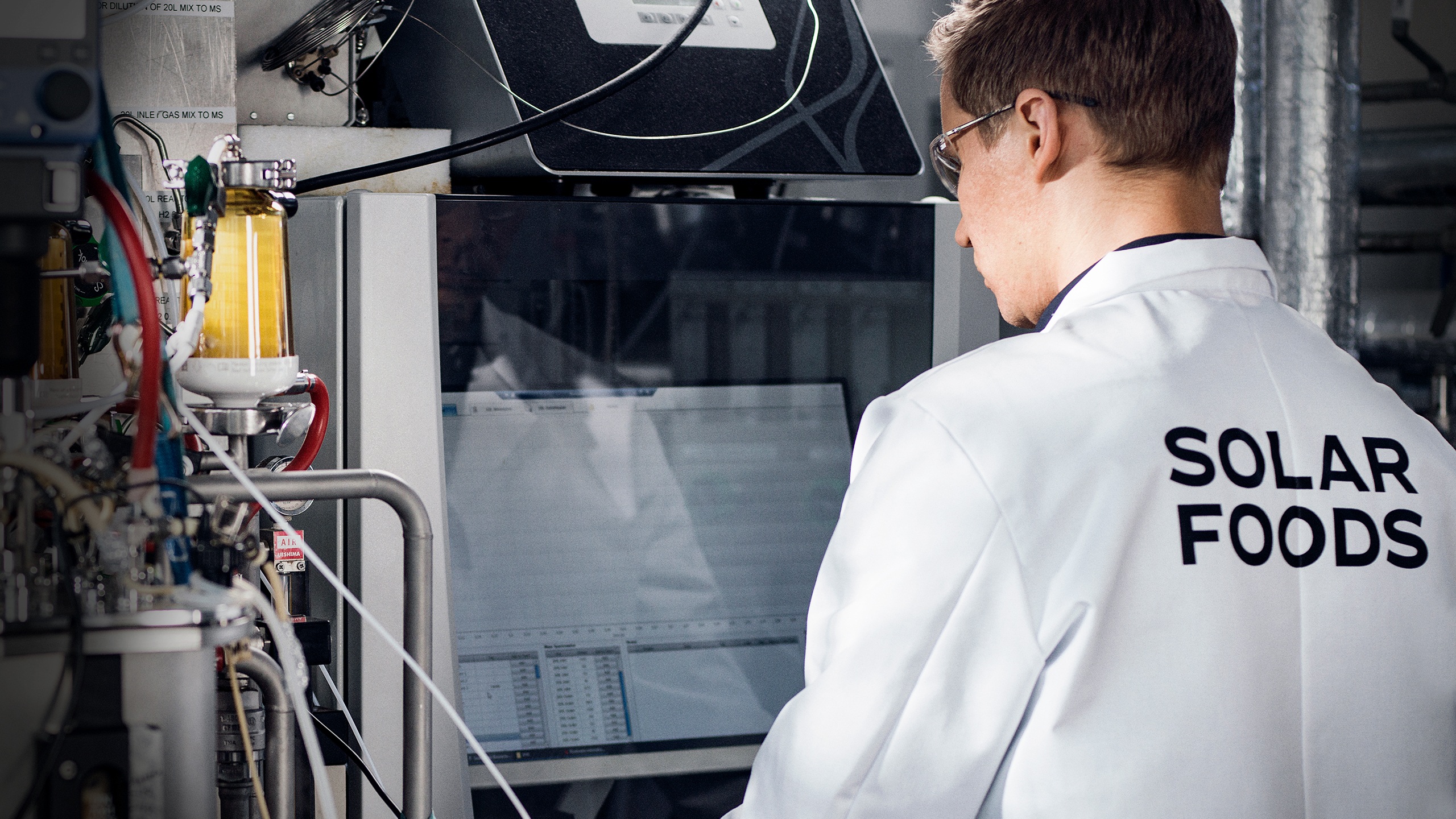

These new kinds of farms are run by new types of farmers, Production Specialists. Their job is to produce the world’s most sustainable protein by using the simplest ingredients possible while operating in an energy efficient manner.

What are these new types of farms like and what does a future farmer actually do? Our very own expert, Head of Bioprocess Development Dr. Petri Tervasmäki, tells more about these new kids of farms and the things future farmers do.

A simple process – without the need for arable land

“The production process for Solar Foods’ protein powder, Solein, starts with a goal in mind: we want to produce food by using the simplest ingredients possible and operating in an energy efficient manner”, Petri states.

The process itself resembles the brewing of beer and at first glance the facility itself looks like a brewery with large tanks, reactors and equipment made of shiny steel. Instead of overalls, our farmers wear white Solar Foods coats and protective wear, working throughout the various production phases. At production everything seems like it’s working at its own pace, in an automated mode, but what seems to be like a simple process, requires careful monitoring and constant care.

Production Specialists are no strangers to rolling up their sleeves, either. Maintaining the smooth process means that the farmers need to get hands-on with the equipment using heavy tools and machinery. Ensuring consistent quality or the product, the farmers snap on their blue rubber gloves to take samples and work in the laboratory. But the most important tool for the future farmer is by far the computer, which allows them to monitor, analyse, and adjust the entire process even from a distance.

“A slight humming sound in the background that comes from centrifuges and motors, is a sign that the process is constantly happening inside the steel skins. There is no detectable odour as the process is mostly closed”, Petri describes.

There is no contact with the product until the downstream when it is being dried into a fine golden powder. When reaching this stage of the production, the farmer enters a separate closed space where the spray dryer is located. Maintaining the highest hygiene standard here is paramount, and that’s why the farmer needs to change into a sealed protective suit.

This all may seem like science fiction, but for the Production Specialist working at the facility, it’s just another day at the farm of the future.

What makes the whole production process a successful one, is how the entire team works together. Each future farmer in the team has a special skill and task. The best teams work seamlessly, together, solving any challenge they might be presented with, exploring new opportunities to constantly improve.

“Our team of Production Specialists are not called specialists for nothing. They are known to never give up. We would not be where we are now without our relentless attitude to find solutions. If there is a problem, there is a solution”, concludes Petri.

Makers of the future

At Solar Foods we are on a mission of liberating the world’s protein production.

Instead of unfounded optimism, we believe that it is possible to find a solution to any challenge with the right methods at your disposal. And finding those methods is the fascinating part.

The future farmers at Solar Foods are, therefore, as fascinated about seeking solutions needed to revolutionise the food industry, as they are about producing the world’s most sustainable ingredient.

Our company decisions, business plan, and products are part of the circle of life on this planet. From research all the way through vision and mission to our products, our company’s purpose is based on being responsible.

At Solar Foods we are not just creating the future, we are already living it.