Growing food in space: how Solein® could feed the astronauts of tomorrow

Written by:

Juha-Pekka Pitkänen

Chief Technology Officer

Conquering space requires novel approaches to nutrition that might sound like science fiction. However, such solutions are closer than most of us think – and they will also help solve the food challenges on Earth.

It has been 52 years since humanity first landed on the Moon. In this age of advancement, that feels like an eternity: society has since transformed many times over as a result of new technological marvels. So why have we not conquered other parts of our solar system, like Mars?

Simple answer: the difficulty of resource management. Space is a hostile frontier where travelers need to bring with them anything they need to survive: oxygen, fuel, tools, and of course, water and food.

Finding ways to feed astronauts far, far from home

Humanity has worked to create tiny footholds in space in the form of crewed space stations, such as the International Space Station. In terms of cosmic distances the ISS is barely a step beyond Earth’s front door, orbiting 400 kilometers above our planet. The Moon sits much farther at 400,000 km but is still (relatively) close in terms of packing supplies: exact time depends on many variables, but a crewed flight could reach the Moon in 2-3 days.

Other planets have still been too far for our resource management abilities. Mars is, on average, ca. 225 million kilometers from Earth. Every two years or so the Mars Close Approach takes place and the two planets are closest to each other on their orbits around the sun. Even then, the distance is vast: on the previous Close Approach in October 2020 Mars was 62 million kilometers from Earth.

Any astronauts headed to the Red Planet would need to commit to a roughly three-year mission. Resupply from Earth would be out of the question in any sudden emergency. To succeed, the Mars astronauts would need to maintain a high level of self-sufficiency: solving their own technical problems, handling their own medical issues, and feeding themselves throughout the mission.

Food is a major challenge because of its weight. If a spaceship to Mars would have a crew of four who would each eat three meals a day, this would mean close to 11 metric tons of food needed over a three-year flight.

NASA and CSA are working to extend humanity’s range of cosmic exploration with the Deep Space Food Challenge that seeks new space food solutions.

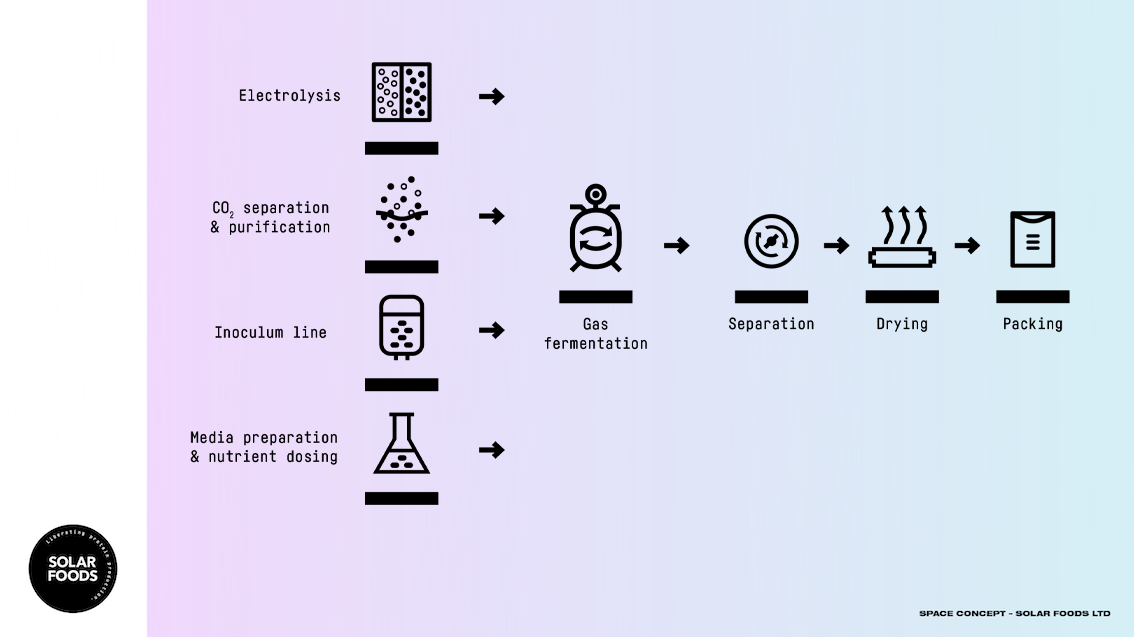

Solar Foods entered the challenge with a production unit that uses our gas fermentation technology to grow SoleinⓇ. We were one of the winners of the Phase 1 of the Deep Space Food Challenge and one of just two companies from outside the US to be awarded for exceptional innovation. You can read more here.

The Deep Space Food Challenge had several criteria for its entries: any suitable food for long space missions should be safe and nutritious, resource-efficient and ideally also tasty to support the psychological well-being of astronauts stuck in space with a limited variety of meals.

Any production unit for this space food also needs to conform to the restrictions of a spaceship. The challenge rules specified the unit should have a volume under 2m3, should pass through a doorway 1.07m wide and 1.9m tall, and fit in a 1.829m X 2.438m X 2.591m room. Its draw of power should average ca. 1,500 watts and be at maximum 3,000 watts.

This was an intriguing test for us. How would Solein work as part of a space traveler’s diet, and how would it be grown within the limitations of a spaceship?

Solein as a space food – and growing it on a spaceship

Astronauts’ diets are highly tailored to meet their personal nutritional requirements and a zero gravity environment. Based on what we know, Solein’s nutritional contents should support and supplement space meals quite well.

Solein is 65-70% protein, 5-8% fat and 10-15% dietary fibers and 3-5% mineral nutrients. 100g of Solein contains 385kcal of energy and has a 171% of the reference daily intake of vitamin B2, more than five times the reference intake of B9 and B12, and a variety of other vitamins.

While taste is one criteria for any food to be viable for a space mission, Solein has the benefit of having no strong taste in itself. This means it more easily vanishes into existing foods: astronauts could mix it with their favored meals or season it to suit their personal palate.

So what would a viable Solein production unit look like aboard a spaceship? Our proposal (designed for a crew of six astronauts) envisioned a unit housed within a 72x162x56cm cabinet, with an average draw of 1,500 watts. The first prototype might weigh approx. 150kg. This is still too much, since any extra weight means considerable costs when it comes to space travel: sending one kilogram to space can cost upward of $20,000.

Shaving 50kg off of the unit’s weight would translate to savings of a million dollars. This is achievable by replacing steel parts and structures with lighter materials. The main challenge is in testing and optimizing a build that is light in weight, durable enough to be shot into space, and reliable in function.

To produce 1kg of Solein a day, the production unit would need ca. 50kWh of power. It would use a 50l tank of water for the bioprocess. Water has an added benefit: it is a good shield from the radiation of space.

Space food is the question of tomorrow – growing food on Earth is today’s challenge

Solein in space might sound like a far-off idea, but in terms of the technology currently at our disposal, it is closer than most probably think. The bioprocess is already in place and needs no changes to work in space: Solein for astronauts would be exactly the same protein that we already grow here on Earth.

Designing and constructing the prototype for a space mission would take a year. Rigorously testing its autonomous function and reliability and optimizing its weight would take a few years, but the project could theoretically go from the drawing board to actual application in 3 or 4 years.

We are excited if Solein can do its part to help humanity reach Mars. However, we also remain committed to solving the issue of food here on Earth. The challenge of space food is a great pressure test: can you make food in a place where it is supposed to be virtually impossible?

Solein’s answer to that is yes. If we can manufacture protein on a spaceship, then there’s no reason why we couldn’t do it anywhere on Earth: in scorching deserts, in freezing Arctic regions, or in the middle of a paved industrial area with no fertile land or farm animal in sight.