The yellow new deal: Factory 01 will start an era of sustainable protein production

Written by:

Ville-Veikko Vaaranmaa

Factory 01 Project Director, Solar Foods

Over two million years ago our hominin ancestors began eating more meat. The protein they ingested kickstarted evolutionary processes that eventually led to the birth of humanity. Protein has driven our success as Earth’s dominant species: to continue this progress, we now need a source of sustainable and climate-proof protein.

Our bodies contain an estimated 100,000 different proteins, all created as combinations of twenty amino acids. Nine of these are essential amino acids, which the body cannot create: we get them from the food we consume.

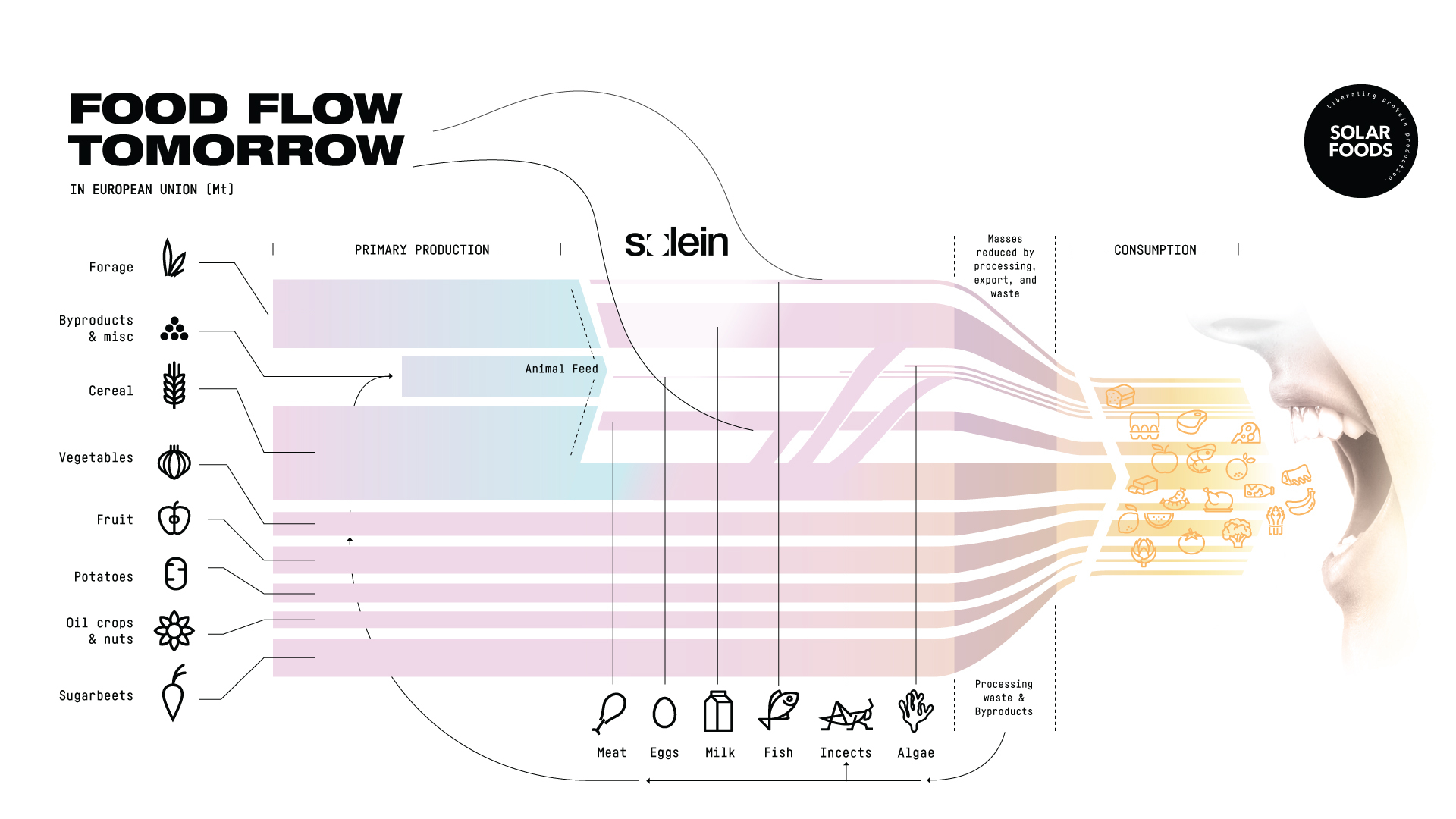

Humanity has come up with countless ways to enjoy the chase of these amino acids and has made protein the main ingredient of our meals. I look at food production from many angles: I’m an engineer, a food scientist, and a friend of great cuisine. True love of food comes with a respect for the origin of food: the planet. Currently, humanity takes more than Mother Earth can provide. We must do better – and that’s where innovations like Solein come in.

Beef, peas or Solein

Growing any protein requires land and water, and inevitably creates emissions. But it matters a great deal how we grow our daily protein.

Tropical forests contain an estimated half of the global biodiversity – and we are destroying them at an alarming rate. If we put a price on the rainforests we are chopping down for agriculture and meat production, ordinary hamburgers would be exorbitantly expensive. For 1kg of beef protein, we need 360m2 of land and over 130,000l of water. With such figures, it is obvious that the world cannot support all of us eating beef. Beef is luxury food, not a staple.

Let’s draw a comparison. Producing a kilogram of pea protein takes 18m2 of land and 68,000l of water. The numbers are clear. Peas are vastly more ecological than beef. But we have an even more resource-efficient alternative: Solein.

To grow a kilogram of Solein, we need just 0.5m2 of land and ca. 1,500l of water. In other words, Solein requires 0.1% of the land and 1% of the water that producing a similar amount of beef does. Its emissions are just 0.7% of that of beef and about half of that of peas.

The production process for Solein is disconnected from agriculture, climate and weather—it is a scalable solution for any geography to create all the different proteins that Earth’s rising population will demand. How does Solein accomplish this? Simple: it radically condenses the process of protein production. Instead of needing all that arable land and freshwater that other proteins require, Solein can be grown from start to finish under one factory roof.

The production process for Solein is disconnected from agriculture, climate and weather—it is a scalable solution for any geography to produce all the different proteins that Earth’s rising population will demand.

Intensive agriculture strains our bonds with Earth

Even with centuries of development and innovation, traditional agriculture and animal husbandry involve drawbacks and vulnerabilities we have not been able to eliminate.

To prosper, crops and livestock need a great deal of water, nutrition, long growing seasons and temperate weather. Even with ideal conditions, farming is hard work: lands need to be cleared to create vast fields, these fields need to be tilled and fertilized, animals fed and tended to, crops sown and harvested, organic waste processed, and so on.

Even after a successful cycle, the harvest still needs to be transported long distances to factories for further processing before it can make its way to supermarket shelves and our dinner tables. This requires a lot of machinery, vehicles, chemicals, farmhands, and energy. The road from farm to fork can be long and its environmental footprint wide.

Taking food production to literal new frontiers

Solein gives us a shortcut to those essential amino acids. It is grown using a natural fermentation process where a natural micro-organism is fed with gases and small amounts of nutrients. The end result is food, but the unsustainable elements of agriculture are minimized or removed from the process.

As Solein needs no farmland to grow, its production is virtually independent of location. It can be grown in factories in the middle of cities, significantly lowering transportation costs, or in environments hostile to normal agriculture. In Arctic regions the factory’s excess heat can benefit surrounding areas through teleheating; hot countries with long daylight hours can source renewable solar energy to power Solein factories.

With technological advancements, we foresee that Solein factories will be operated mostly remotely. These facilities can operate throughout the year without compromising any part of the harvest to cold spells, droughts, or storms.

The low-emission production process combined with an efficient, predictable output translates to a meaningful climate impact.

We can have our protein and eat it too

Growing Solein involves some fixed early costs when facilities, equipment and production lines are set up. But once production starts, resource costs and emissions rapidly drop to a fraction of ordinary agriculture. The system can be scaled with little to no upper limit.

We recently broke ground with our first commercial production facility, Factory 01, in Vantaa. It is set to be the first facility ever to house an entire commercial food system from agriculture to production lines to processing all under the same roof.

Solein signals a more sustainable future for the food industry: fewer rainforests cut down for fields or pastures, more biodiversity through crop rotation and organic farming – and still enough food to feed the world. There are plenty of hurdles to cross, but we are on our way to an era where eating well and respecting nature will not be mutually exclusive anymore. That’s the yellow new deal.

Ville-Veikko Vaaranmaa

Factory 01 Project Director, Solar Foods

Ville-Veikko leads the scaling up of Solar Foods’ production capabilities, construction and commissioning of the upcoming Factory 01. He has more than 25 years of experience working with food technology investment projects.