An elemental perspective to food production – Solar Foods produces a novel ingredient out of electricity and air

Dr Juha-Pekka Pitkänen

CTO, Co-founder, Solar Foods

“What are little boys made of? What are little girls made of?” In terms of chemical elements, the answer to the famous nursery rhyme would be: carbon, hydrogen, oxygen and nitrogen.

Those four elements make ca. 97% out of the human body mass. In addition, we need around 20 other chemical elements that have a known role in our bodies. Overall a human being contains 60 chemical elements in measurable quantities, including 0.2 mg of gold.

The human body has to receive its necessary chemical elements in forms that are easily digestible and ingestible: carbohydrates, proteins and fats. These serve as the energy sources for our bodies. From the structures of these core nutrients we also receive some mineral nutrients, such as phosphorus and sulfur. Some minerals we acquire in an inorganic, ionic form, such as sodium, potassium and chlorine.

In addition to these, a human being requires vitamins. Their structures contain the rarest trace elements we need. A good example is the B12 vitamin – in the core of its complex structure lies the cobalt atom.

Target: energy efficient protein production

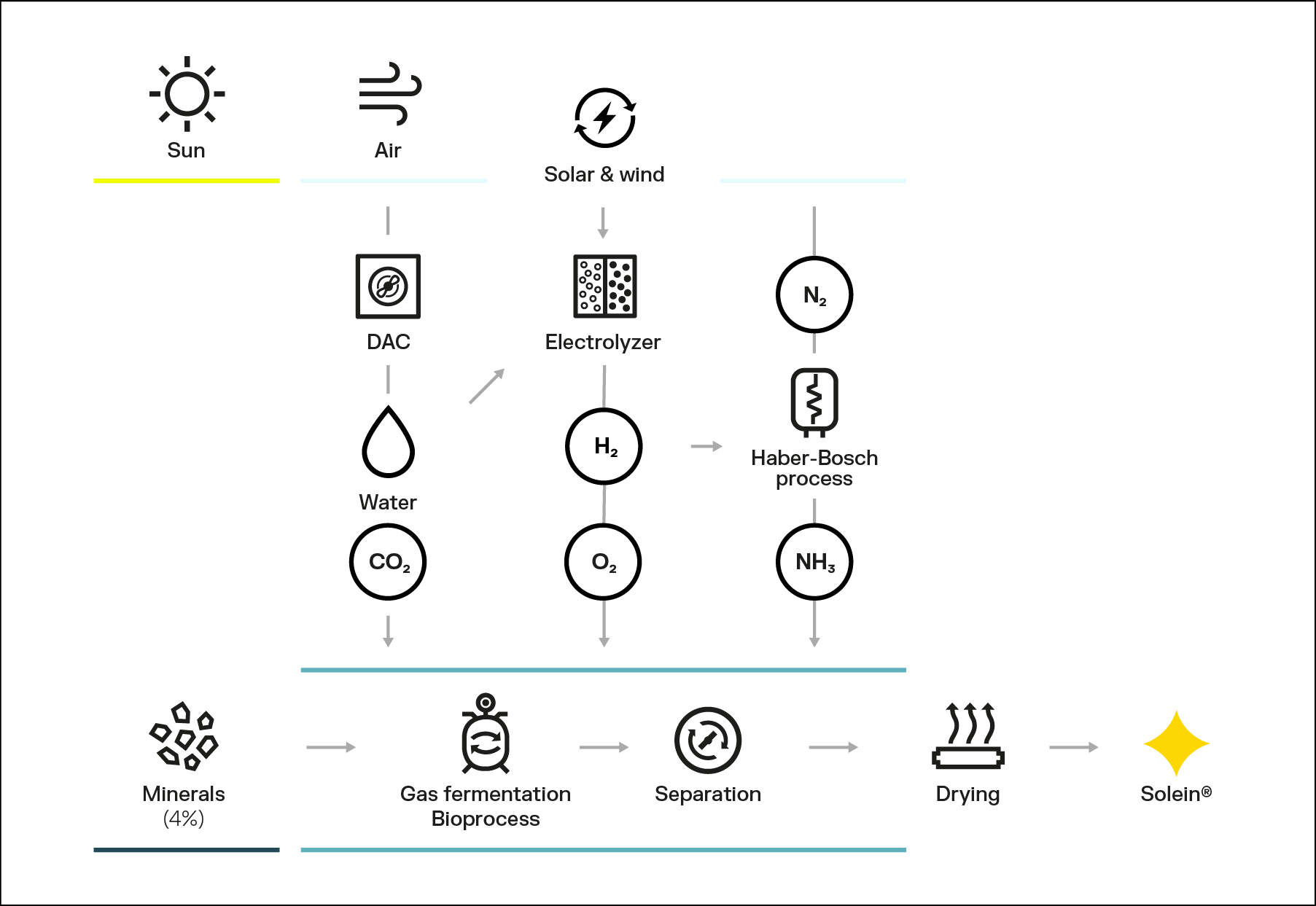

The production process for Solar Foods’ protein powder, Solein®, starts with a goal in mind: we want to produce the nutrients the human body needs by using the simplest ingredients possible and operating in an energy efficient manner. The process is based on a simple microorganism that grows using carbon dioxide as its source of carbon, and hydrogen gas as its source of energy.

The hydrogen gas is produced by splitting water in an electrolyzer. Some of the oxygen created in the electrolysis is used in the process, while some of it is released into the atmosphere. The process uses ammonium as a source of nitrogen. These are the four main elements the process must have and they can all be sourced out of thin air.

Using DAC equipment (Direct Air Capture), we can gather carbon dioxide and water from the air. Ammonium is already produced through the Haber-Bosch process out of air-captured nitrogen, but the hydrogen gas that is needed still comes from natural gas. So-called green ammonium uses a process where the hydrogen gas is produced in an electrolysis powered by renewable energy. This production process for green ammonium will likely be considered the first major mass product for the hydrogen economy.

A simple process – without the need for arable land

In Solein’s production process, the microorganism creates all the carbon compounds it needs (e.g. amino acids, carbohydrates, fatty acids) out of carbon dioxide. It is what’s known as an autotrophic organism, or a primary producer. Plants are also primary producers but unlike them, the microorganism does not source its energy from sunlight but from hydrogen gas. In addition to carbon dioxide, hydrogen gas, oxygen and ammonium the process still has to have the 20 or so elements that a human being also needs. They are introduced to the process by adding mineral salts.

The process itself resembles the brewing of beer. It takes place as a constant growth process in a bioreactor where the microorganism is allowed to fulfill its life’s purpose and grow freely. In the postprocessing phase the product is pasteurised, most of the water removed through separation, and the resulting Solein is dried until it becomes powderlike. In the end, the fully processed Solein contains ca. 78% protein, 10% fiber, 6% fat, 2% carbohydrates and 4% minerals.

The image below helps you understand how all of it works. As a whole, it is quite a simple process. Its secret lies in the microorganism: a simple organism compared to a the human body, but still able to produce thousands of different compounds, including vitamins such as B12.

One of the most significant differences this process has when compared to plant vegetation is that it doesn’t need arable land or favourable climate conditions. Instead, the process requires renewable energy, such as solar or wind power. If we compare Solein produced with solar power to plants, the plants need approximately ten times the arable land area in order to produce a similar amount of nutrition as Solein. In the future, humanity will be able to reforest arable land areas once more as food production can become more efficient and take place in regions where farming used to be impossible because of conditions such as drought.